Rules for Using Ribs to Strengthen Plastic Injection Molded Parts

4.6 (264) In stock

Jan 17, 2017 11:04:42 PM / by Jon Gelston It’s not uncommon for a small plastic injection molded part to be expected to hold up under a large load. One of the ways to strengthen a part is by adding one or more “ribs” to the design.

How to Add Ribs to Prevent Risks for Your Part Design - Natech Plastics

Chinaplas 2017

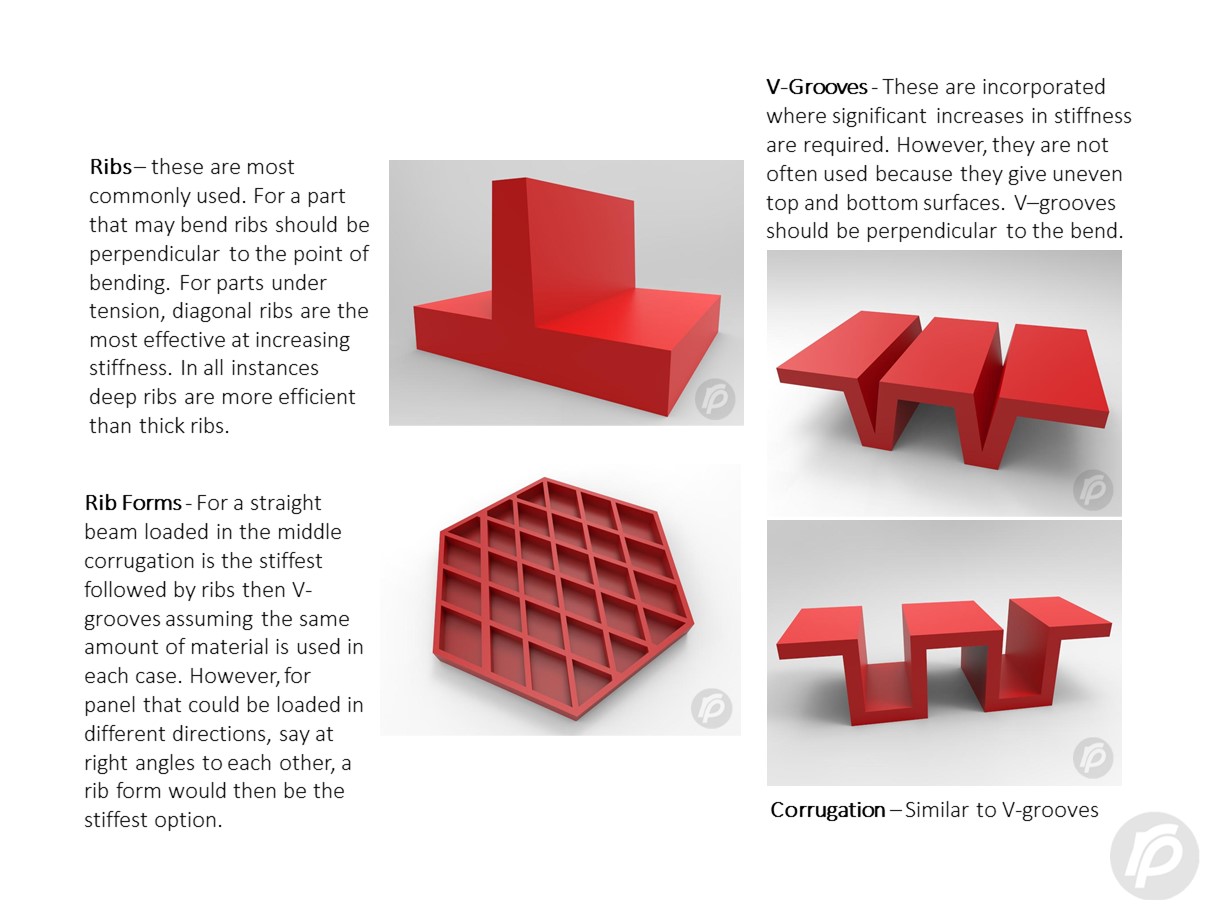

Design For Stiffness - Rutland Plastics

Design Stronger Molded Parts: Ribs, Gussets, and Materials

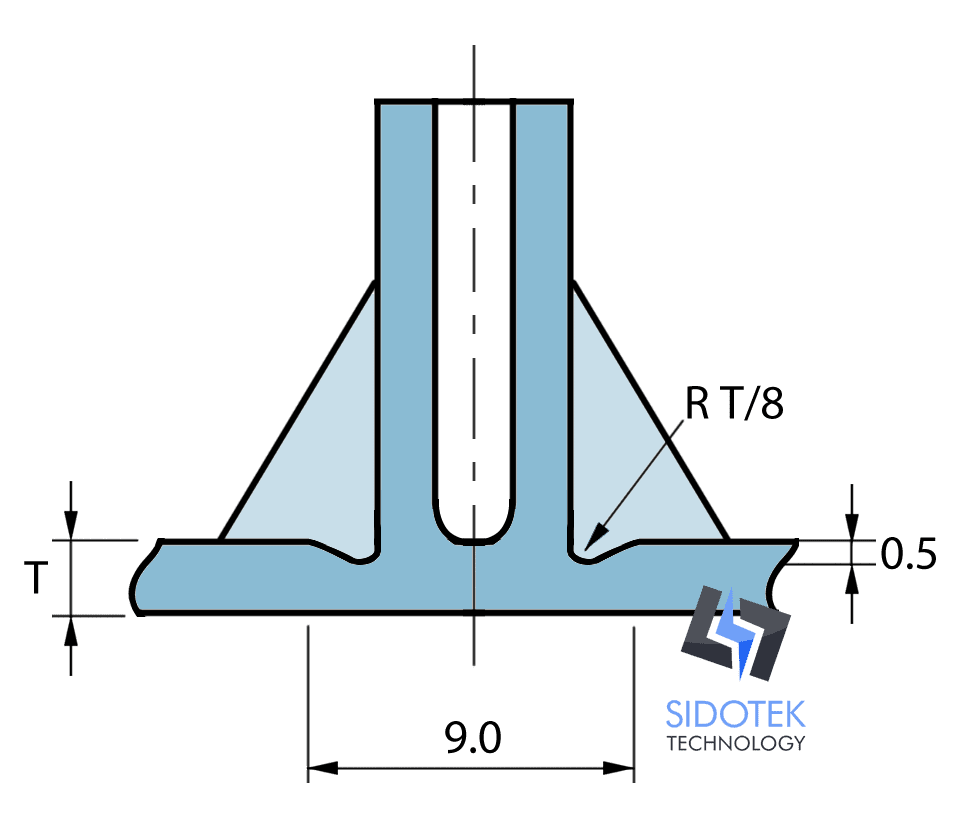

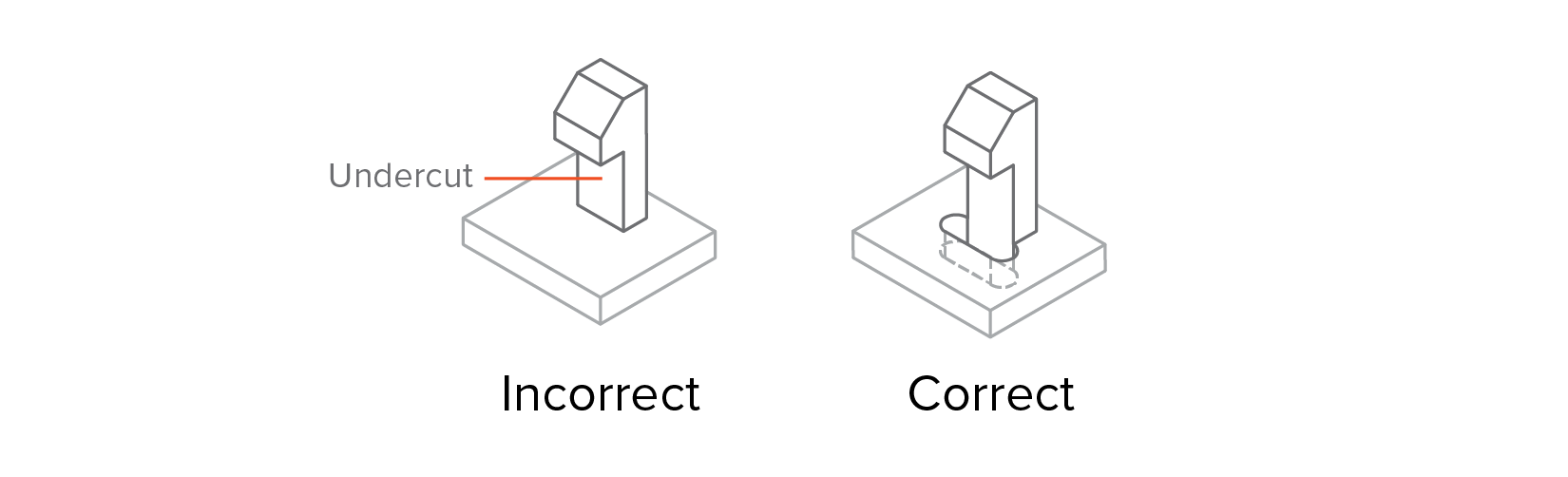

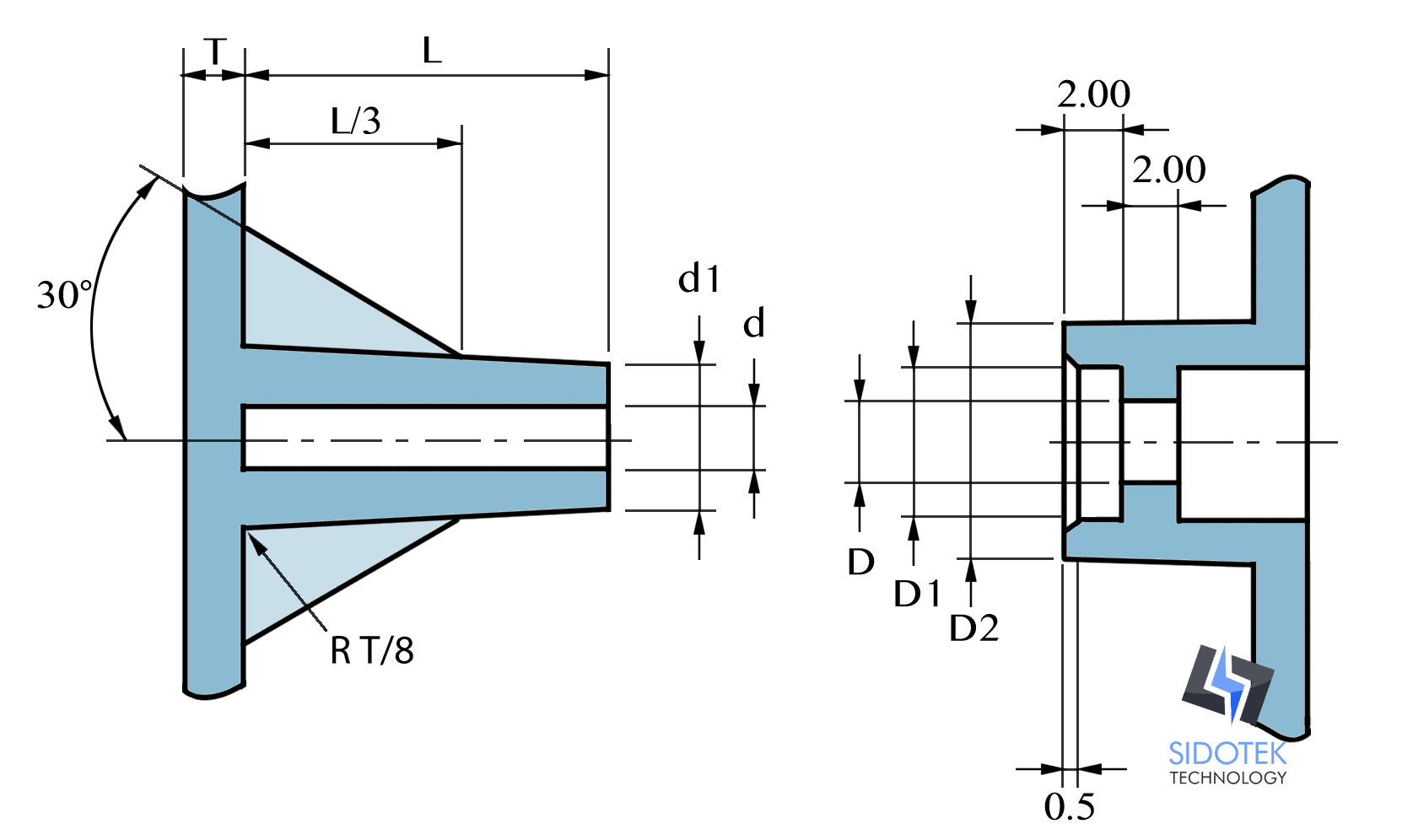

Ribs and Bosses Design Guidelines in Plastic Parts – SIDOTEK TECHNOLOGY

Injection Molding: Rib Design - 3 Space

Aim Processing Blog Small Plastic Parts

The Benefits of Elastomeric Overmolding

A Completely Plastic Part Design Guide for Injection Molding

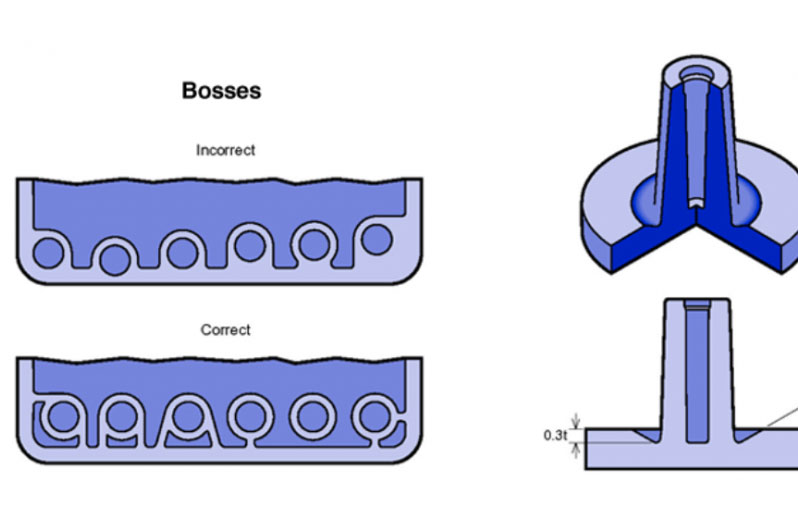

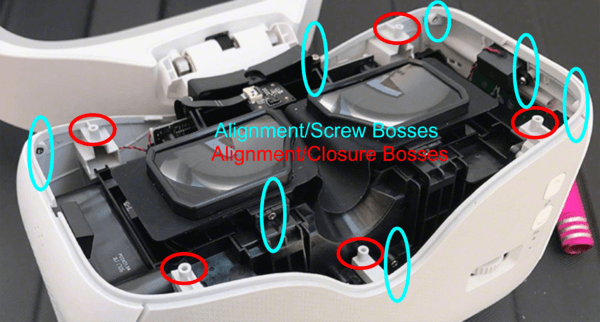

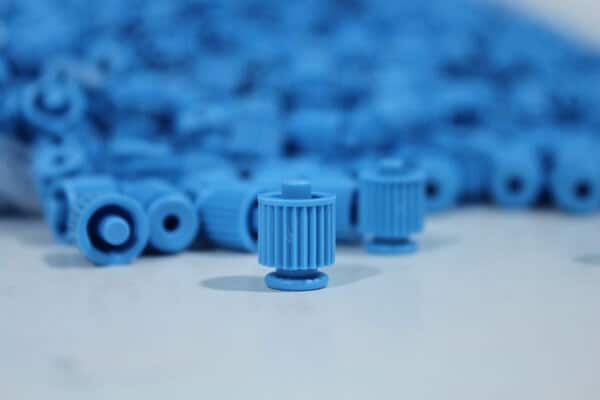

All About Bosses In Injection Moulding

Guide For Plastic Injection Molding

Design Stronger Molded Parts: Ribs, Gussets, and Materials

Injection molding: The manufacturing & design guide

Ribs and Bosses Design Guidelines in Plastic Parts – SIDOTEK TECHNOLOGY

The Cardinal Rules of Designing Injection Molded Plastic Parts

adidas Men's Tiro 21 Sweatpants | Comfortable & Stylish Soccer Pants

adidas Men's Tiro 21 Sweatpants | Comfortable & Stylish Soccer Pants Itching breast, areola, nipple, bust: how do I get relief?

Itching breast, areola, nipple, bust: how do I get relief? Find Cheap, Fashionable and Slimming busty corset lingerie

Find Cheap, Fashionable and Slimming busty corset lingerie Featured Wholesale Brass Goblet India to Bring out Beauty and

Featured Wholesale Brass Goblet India to Bring out Beauty and CoolSculpting vs. Liposuction: 3 Things to Consider - Dr. Hess

CoolSculpting vs. Liposuction: 3 Things to Consider - Dr. Hess SUPER SKINNY MID-RISE Old Navy 2 Petite Jeggings Jeans Elastic Waist Pull On

SUPER SKINNY MID-RISE Old Navy 2 Petite Jeggings Jeans Elastic Waist Pull On