Reducing black dots defects! Features of the purging pellet ecomaru - ecomaru, high cleaning purging pellet

4.6 (757) In stock

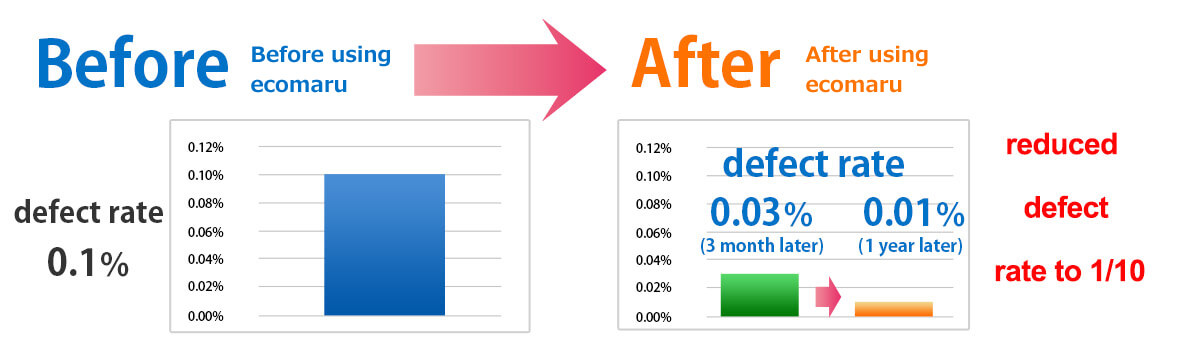

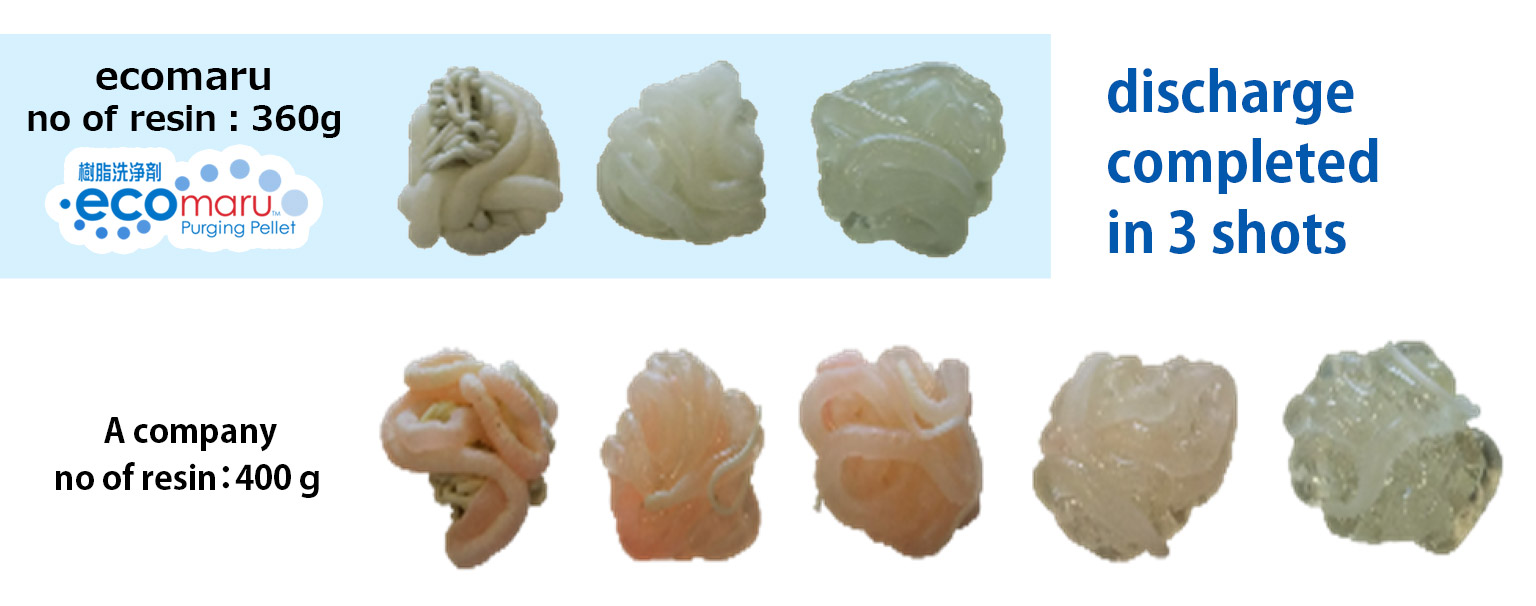

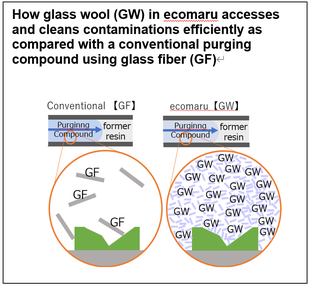

quot;ecomaru" is purging pellet specially developed and made for cleaning the inside of cylinders for injection molding machine. Highly mixing with GW (glass wool), the highest priority is on black dots removal performance. It makes great contributions to quality improvement by removing and preventing resin deterioration (burning and black dots) in cylinder that was not able to be completely removed by GF (glass fiber) and reducing the foreign material defect rate such as black dots defects.

d2n4wb9orp1vta.cloudfront.net/cms/Complex%20downst

Eliminate Black Specks & Carbon Contamination

Reducing black dots defects! Features of the purging pellet ecomaru - ecomaru, high cleaning purging pellet

Why do black spots and white spots appear when processing aluminum

Tpu 95a Pellets Conductive Carbon Black Manufacturers and

What is purging pellet ecomaru ? - ecomaru, high cleaning

Reducing black dots defects! Features of the purging pellet

ecomaru - ホーム

R2-064 ナノダックス株式会社(プラスチック成形機用洗浄剤 ecomaru

Cause analysis and solutions for black spots and breakage of waste

Improvement of defect rate and use of Pareto charts

Defect Arrival and Kill Rate - Quickscrum

8 Ways To Improve Your Order Defect Rate [ Complete Seller's Guide ] - The Fastest Repricer

How to fetch count of different IssueTypes [Defect Rate] - Questions & Answers - eazyBI Community

Confidence Interval for Defect Rate in Simulator - JMP User Community

NWT Old Navy Yeti Abominable Snowman Camping Out Jogger Pajama Pants Men S M

NWT Old Navy Yeti Abominable Snowman Camping Out Jogger Pajama Pants Men S M A moment for Java. ☕️ Also, if you're a breastfeeding mama, this SKIMS nursing bra in cocoa is pretty much identical to Java!! And soooo comfy. Fit details in comments : r/lululemon

A moment for Java. ☕️ Also, if you're a breastfeeding mama, this SKIMS nursing bra in cocoa is pretty much identical to Java!! And soooo comfy. Fit details in comments : r/lululemon Bras Sets Bdsm Leather Full Body Harness Open Breast Bra Leg Garter Belt Set For Women Gothic Sexy Cage Bondage Erotic Lingerie

Bras Sets Bdsm Leather Full Body Harness Open Breast Bra Leg Garter Belt Set For Women Gothic Sexy Cage Bondage Erotic Lingerie:max_bytes(150000):strip_icc()/Epidote-58bd7f2a5f9b58af5cb2f5f8.jpg) Common Green Rocks and Minerals

Common Green Rocks and Minerals DSG Outerwear Chloe Hooded Sun Women's Realtree Shirt

DSG Outerwear Chloe Hooded Sun Women's Realtree Shirt Full Cup or Balcony Style Bra, Which is Best?

Full Cup or Balcony Style Bra, Which is Best?