Pull-test standards and methods

5 (526) In stock

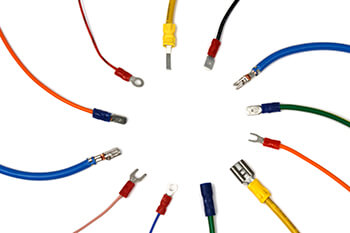

Pull test standards and methods Background The quality of a crimp joint depends on the mechanical strength of the joint as well as its electrical conductivity. If results from pull force tests are within an allowed range, it assures that the proper crimp force has been applied during the crimping process.

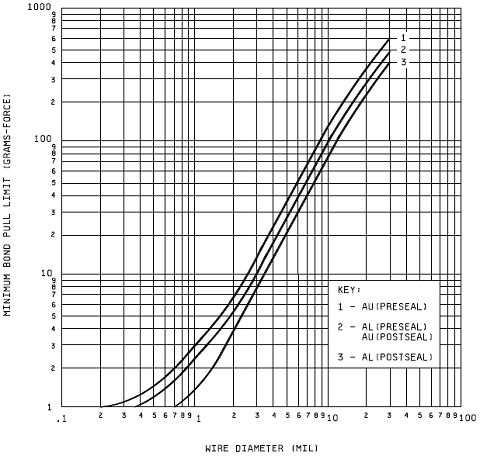

MIL-STD-883 2011.9 - Bond strength (destructive pull test)

Pull-Off Adhesion Testing of Coatings – Improve Your Technique

The Importance of Pull-Out Test in Commercial Metal Sheet Roof

The Importance of Pull-Out Test in Commercial Metal Sheet Roof

PDF) Children's Apparel & Accessories – Product Safety Guidelines

What is Pull Testing? - Streval Structural Evaluation

Button Pull Test SOP - ORDNUR

Cable harness - Wikipedia

Pull-off/Pull-out KC

The Importance of Pull-Out Test in Commercial Metal Sheet Roof

Cable harness - Wikipedia

The Importance of Pull-Out Test in Commercial Metal Sheet Roof

How-To: Properly Crimp Wires and Terminals - Hughs Hand Built

Soldering or Crimping: Which Is Better for Your Electrical Needs? - CAI

3 Crimped Wire Wheel - 1/4 Shank (Stainless Steel)

Time sensitive) how do I remove wires that have been crimped? : r

Victoria's Secret unlined 34C,34DDD,36DD BRA SET M BLACK sequined VELVET VELOUR

Victoria's Secret unlined 34C,34DDD,36DD BRA SET M BLACK sequined VELVET VELOUR Bombshell Add-2-Cups Shine Strap Lace Push-Up Bra

Bombshell Add-2-Cups Shine Strap Lace Push-Up Bra Ultra-thin Breathable Seamless Panties Ice Silk Women's Underwear

Ultra-thin Breathable Seamless Panties Ice Silk Women's Underwear Adoretex Girl's/Women's Printed One Piece Thin Strap Athletic Swimsuit

Adoretex Girl's/Women's Printed One Piece Thin Strap Athletic Swimsuit JDEFEG Womens Pants Casual Plus Size Womens Lined Leggings Thermal High Waist Pants Winter Workout Running Tights V Shape Leggings for Women

JDEFEG Womens Pants Casual Plus Size Womens Lined Leggings Thermal High Waist Pants Winter Workout Running Tights V Shape Leggings for Women high-waisted-tummy-control-leggings-top-3-piece-set-2-piece-set -954157.jpg?v=1704441663

high-waisted-tummy-control-leggings-top-3-piece-set-2-piece-set -954157.jpg?v=1704441663